Fractional Mud Pump Stroke Counter

Product Details:

- Response Time < 50 ms

- Wireless Optional wireless transmission capability

- Interface RS232/RS485, relay contact, or 4-20mA

- Mounting Type Panel, wall, or bracket mounted

- Power Consumption < 5W

- Sensor Type Reed switch/magnetic proximity or mechanical sensor

- Operating Temperature -10°C to +55°C

- Click to view more

Fractional Mud Pump Stroke Counter Price And Quantity

- 1 Unit

- CE & ISO 9001:2015 certified

- Supports up to 300 strokes/minute

- Corrosion-resistant, sealed enclosure for harsh environments

- Multi-digit backlit LCD with fractional indicator

- Comes with universal mounting kit and cable glands

- Non-contact magnetic pick-up or direct mechanical interface

- Industrial grey/black

- Onboard memory for 30 days of stroke history

- Factory calibrated, field recalibration supported

- User-adjustable high/low stroke alarm with buzzer output

Fractional Mud Pump Stroke Counter Product Specifications

- < 50 ms

- RS232/RS485, relay contact, or 4-20mA

- Optional wireless transmission capability

- Panel, wall, or bracket mounted

- -10°C to +55°C

- Reed switch/magnetic proximity or mechanical sensor

- ±1 stroke or better

- < 5W

- High-grade alloy and ABS plastic

- Oilfield drilling rigs, mud pump monitoring

- Counts and displays pump strokes—fractional and total

- Fractional Mud Pump Stroke Counter

- 0-9999 strokes

- Standard 5m (custom lengths on request)

- Pulse or digital

- Approx. 2.5 kg

- Digital display, relay or analog output (optional)

- Backlit LCD, resettable counter, rugged construction

- Mechanical or electrical pulse from mud pump

- IP65

- High (detects weak pulses)

- Real-time pump stroke monitoring and measuring

- 0.1 stroke

- 12V/24V DC (optional AC adapter)

- CE & ISO 9001:2015 certified

- Supports up to 300 strokes/minute

- Corrosion-resistant, sealed enclosure for harsh environments

- Multi-digit backlit LCD with fractional indicator

- Comes with universal mounting kit and cable glands

- Non-contact magnetic pick-up or direct mechanical interface

- Industrial grey/black

- Onboard memory for 30 days of stroke history

- Factory calibrated, field recalibration supported

- User-adjustable high/low stroke alarm with buzzer output

Fractional Mud Pump Stroke Counter Trade Information

- MUMBAI

- Cash Advance (CA)

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- Asia

- All India

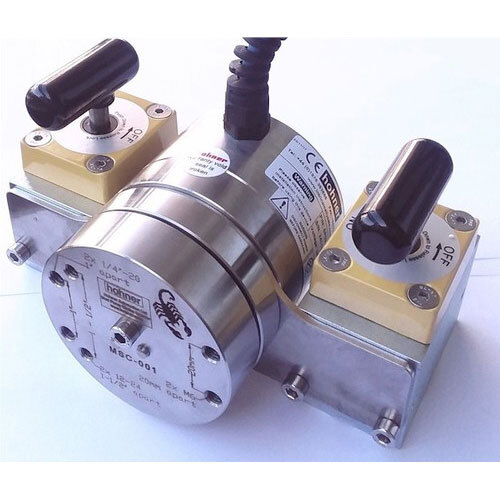

Product Description

Technical Data

|

Operating temp: |

- 20 ...+ 60 degrees C |

|

|

- 4 ...+ 140 degrees F |

|

Certification: |

ATEX, IECEx, CSA |

|

Weight: |

6.6 lbs (3.0 kg) |

|

Protection: |

IP 66 / X7 M |

|

Material Sensor: |

Stainless Steel |

|

Material Spring: |

Stainless Steel |

|

Material Arm: |

Stainless Steel |

|

Material Bracket: |

Stainless Steel |

|

Resolution: |

0.18mA = 1 degree |

Output

To calibrate the unit, mount counter at the beginning of the stroke movement instead of the end like a micro-switch. The pushrod will then push the arm outwards. At the outermost point set the HIGH point, as the pushrod moves back, the spring mechanism brings the arm back in. At the innermost points set the LOW point. You can now measure the two end points consistently, and also all points in between.

Rugged Performance in Demanding Environments

Built from high-grade alloy and ABS plastic, the mud pump stroke counter is engineered to withstand oilfield conditions. Its corrosion-resistant, sealed enclosure assures dependable operation in harsh, wet, or dusty environments, meeting IP65 standards for ingress protection. The industrial grey/black casing blends durability with a professional appearance.

Accurate, Real-Time Monitoring with Advanced Features

This device counts both fractional and total pump strokes, displaying results on a crisp backlit LCD with 0.1 stroke resolution. User-adjustable alarms help operators react quickly to stroke rate anomalies, while onboard memory logs 30 days of activity. Data can be accessed via digital display, relay output, or analog signal, ensuring integration with your monitoring system.

Flexible Installation and Seamless Integration

Delivered with universal mounting hardware and cable glands, the stroke counter is easy to install on panels, walls, or brackets. It supports both non-contact magnetic and direct mechanical input, offering flexibility for various mud pump configurations. With optional wireless transmission, RS232/RS485 interfaces, and AC/DC power choices, integration into your rigs infrastructure is streamlined.

FAQs of Fractional Mud Pump Stroke Counter:

Q: How is the Fractional Mud Pump Stroke Counter installed and what mounting options are available?

A: The counter comes with a universal mounting kit suitable for panel, wall, or bracket installation. Cable glands and a standard 5-meter cable (custom lengths available) ensure secure and adaptable wiring, allowing for straightforward setup in various rig environments.Q: What type of display does the stroke counter use, and how does it enhance usability?

A: It utilizes a multi-digit backlit LCD display with a fractional indicator, providing clear, real-time visualization of both fractional and total strokeseven in low-light conditions. The high-resolution (0.1 stroke) display aids precise monitoring and early detection of anomalies.Q: When should the onboard alarm be set, and how does it function?

A: The user-adjustable alarm can be programmed for high or low stroke thresholds based on operational requirements. When the pre-set value is reached, an integrated buzzer sounds, immediately notifying personnel of potential issues needing prompt attention.Q: Where can the stroke counters data be accessed, and how is stroke history logged?

A: Data is accessible via the backlit LCD, digital outputs (relay, RS232/RS485, or 4-20mA), and, if equipped, wireless transmission. The device logs 30 days of stroke data onboard, enabling trend analysis and simplifying maintenance planning.Q: What process is followed for calibrating the device in the field?

A: The unit is factory calibrated for out-of-box accuracy. However, should field conditions require adjustment, guided recalibration can be performed. This ensures accuracy remains within 1 stroke, leveraging the intuitive interface for minimal downtime.Q: How does the stroke counter benefit drilling operations and enhance safety?

A: Continuous, real-time monitoring helps detect deviations in pump performance early, reducing downtime and preventing costly equipment failures. The alarm and logging features support proactive maintenance and safer operations, contributing to both efficiency and workplace safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+